Pabrik Pencampur Agregat Aspal

- TTM

- QUANZHOU, FUJIAN

- 30-35 HARI

- 20 SET PER BULAN

Bagian pencampuran:

Mixer ini merupakan mixer poros ganda yang dioperasikan oleh kotak roda gigi dengan sinkronisasi roda gigi, sederhana dan mudah dirawat. Penyelarasan dan alokasi dayung menghasilkan efek pencampuran terbaik setelah pengalaman tahunan. Manufaktur yang canggih memastikan stabilitas kinerja. Terdapat kunci pengaman di pintu inspeksi untuk melindungi manusia. Mixer dilengkapi dengan insulasi panas dengan minyak diatermik dan dengan saluran masuk untuk SMA dan RPA, mudah untuk mesin SMA dan RAP.

Bagian Sistem Kontrol:

Kontrol komputer ganda dengan PLC, tanpa tombol, kontrol otomatis penuh, mudah dioperasikan, ramah pengguna, dan andal. Sistem ini dilengkapi dengan alarm kesalahan dan analisis otomatis, pemantauan waktu nyata, dan layanan jarak jauh.

----- Peralatan pengaspalan aspal 160t/jam ------

1. Jenis:LB-2000

2. Produksi:160t/jam

3. Tempat Penyimpanan Agg Panas:28m3

4. Kapasitas:2000 kg

----------Fitur Utama------------

1. Sabuk pengumpanan dirancang dengan penyekat, yang membuat sistem pengumpanan material stabil dan lancar.

2. Struktur penerbangan drum pengering yang dioptimalkan membuat sistem pengeringan lebih efektif dan stabil.

3. Lift panas mengadopsi rantai Gall ganda untuk pengangkatan, yang tidak hanya memperpanjang masa pakai mesin pengangkat tetapi juga meningkatkan stabilitas pengoperasian.

4. Layar mode linier yang digerakkan oleh vibrator impor meningkatkan efisiensi penyaringan dan mengurangi tingkat kegagalan pabrik.

5. Tempat penampungan agregat panas berkapasitas besar membuat pengoperasian lebih mudah.

6. Dayung kami yang didesain unik dan mixer yang kuat memungkinkan operasi pencampuran menjadi lebih mudah, efektif, dan andal.

7. Sistem penghilang debu dua tahap dan desain antidebu bertekanan negatif menjadikan pabrik pencampur aspal kami ramah lingkungan dan ekonomis.

8. Sistem yang dikontrol komputer, dapat dialihkan otomatis/manual, dan program diagnosis mandiri otomatis membuat pengoperasian menjadi mudah dan aman.

9. Desain modular keseluruhan membuat transportasi dan pemasangan lebih mudah dan cepat.

10. Antarmuka RAP dicadangkan untuk peningkatan fasilitas RAP panas.

Seri LB (tanpa silo penyimpanan jadi) | |||||

Jenis | Produksi | Tempat Sampah Agg Panas | Kapasitas | Tempat Penyimpanan Selesai | Akurasi Penimbangan |

LB-600 | 48 ton/jam | 7m3 | 600kg |

TIDAK

|

Agregat: ± 0,5% Pengisi: ± 0,5% aspal :±0,25%

|

LB-800 | 64 ton/jam | 7m3 | 800kg | ||

LB-1000 | 80 ton/jam | 10 m3 | 1000 kg | ||

LB-1200 | 96 ton/jam | 10 m3 | 1200kg | ||

LB-1500 | 120 t/jam | 30m3 | 1500kg | ||

LB-2000 | 160 t/jam | 50m3 | 2000 kg | ||

LB-2500 | 200 t/jam | 50m3 | 2500kg | ||

LB-3000 | 240 t/jam | 50m3 | 3000kg | ||

LB-4000 | 320 t/jam | 50m3 | 4000 kg | ||

----------Rincian Produk-----------

1. [ Bagian Layar Getaran ]

Layar getar linier dioperasikan oleh motor getar ganda merek Italia. Bebas perawatan. Pintu depan dan belakang, pemasangan kasa tarik-masuk, mudah diganti.

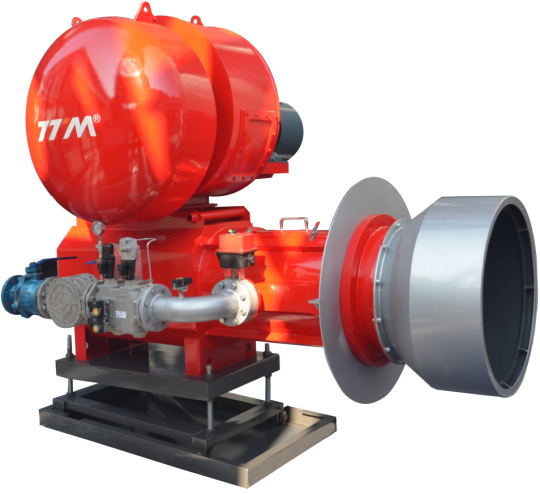

2. [ Bagian Pembakar ]

Pembakar bertekanan rendah dirancang untuk drum pengering dengan kontrol digital pada rasio udara/minyak dan frekuensi, untuk memastikan nyala api yang lebih baik sesuai drum, untuk mengurangi konsumsi minyak secara signifikan. Kontrol pembakar terintegrasi dengan kontrol pabrik, mudah dioperasikan, aman, dan andal. Cocok untuk solar, minyak berat, dan gas alam.

3. [ Bagian Drum Pengering ]

Desain terpadu dari drum pengering, pembakar, dan rumah kantong. Isolasi panasnya menggunakan serat aluminium silikat, efektif dan ramah lingkungan.

----------Perlindungan Lingkungan-----------

1. Pengumpulan debu total dengan pengumpulan inersia tingkat 1, rumah kantong tingkat 2, dan modul pengumpulan debu untuk berbagai bagian fasilitas.

2. Kami menetapkan konsep perlindungan lingkungan sesuai dengan standar Eropa untuk dicapai dalam emisi debu, emisi asam, dan pengendalian kebisingan, dll.

3. Fasilitasnya selaras dengan lingkungan di mana pun kita berada.

---------- Pengepakan Pengiriman -----------

------------- Layanan Kami-----------

Materi teknis, garansi dan layanan gratis:

1. Kami akan menawarkan pelatihan gratis kepada pembeli untuk operator dan pekerja pemeliharaan mereka, dan juga menyediakan layanan saran teknis gratis;

2. Dan perusahaan akan menyelenggarakan kursus pelatihan teknologi secara berkala, dan memberikan pelatihan gratis kepada operator pembeli.

Layanan pasokan suku cadang tepat waktu:

Perusahaan kami menawarkan suku cadang asli, autentik, dan berkualitas untuk aksesori perawatan mesin.

Instalasi dan komisioning dan penerimaan:

1. Perusahaan kami akan menawarkan kepada pembeli bantuan gratis dalam pemasangan peralatan dan komisioning satu kali;

2. Setiap unit setelah pemasangan akan dilakukan kunjungan balasan oleh departemen khusus;

------------- Pertunjukan Adil -------------